Cosmetics & Personal Care Applications

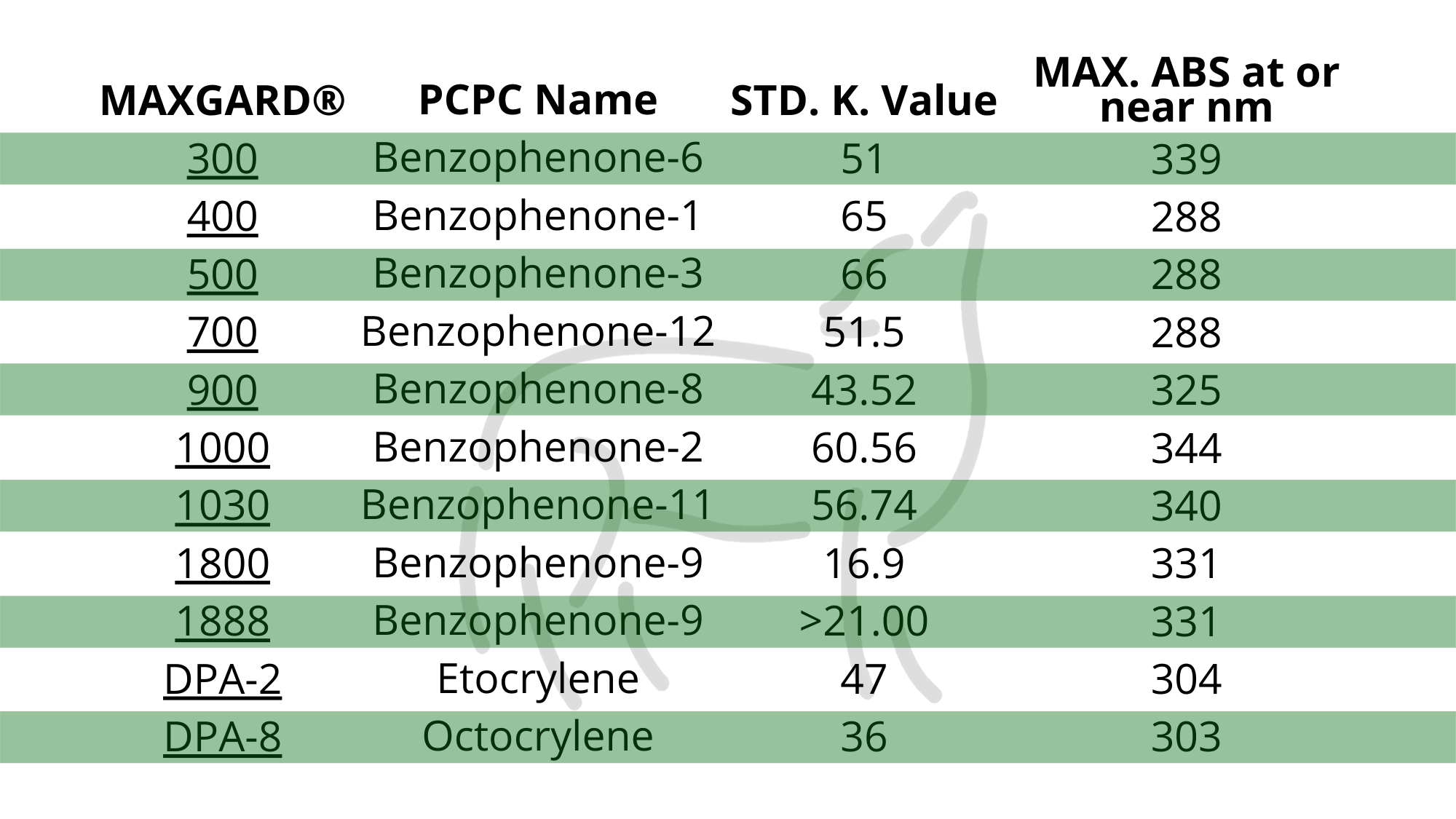

The MAXGARD® UV Absorbers listed below work to protect cosmetic and personal care items from damaging UV radiation. Added to a customer's formulation each of our products have unique, effective applications against harmful UV rays. The MAXGARD® UV Absorbers listed below have been evaluated by the Cosmetic Ingredient Review which was established in 1976 by the industry trade association (then the Cosmetic, Toiletry, and Fragrance Association (CTFA), now the Personal Care Products Council (PCPC)), with the support of the U.S. Food and Drug Administration and the Consumer Federation of America. Although funded by the Council, CIR and the review process are independent from the Council and the cosmetics industry. CIR operates under a set of procedures.

When you hear “Benzophenone” think MAXGARD®

The ingredients in benzophenone are used to absorb and dissipate UV radiation, which is essential in beauty and personal care products. Benzophenone is in a multitude of cosmetic products, but is most commonly found in lip balm, nail polish, foundations, baby sunscreens, fragrances and perfumes, shampoos and conditioners, hair spray, and moisturizers. Benzophenone-UV filters (BP-UV filters) are often used in these cosmetic products to avoid the damaging effects of UV radiation. Benzophenone is used in fragrances as both a scent and color enhancer. Benzophenone is also used to ensure products like soaps don’t lose their scents and colors in the presence of UV radiation.

There are innumerable uses of benzophenone in the cosmetic industry. Benzophenone -1 is a UV stabilizer that is used in sunscreens and cosmetics to stop discolouration of products. Benzophenone -2, Benzophenone -6, and Benzophenone -8 are used as UV absorbers in formulating aftershave lotion, bath products, bubble baths, colognes, perfumes, eye makeup removers, and other skin and hair care products. Benzophenone-4 helps to stabilize UV sensitive formulations such as hair dyes and hair sprays. It also provides protection of colorants against fading and helps stabilize fragrances and active ingredients against oxidation. Benzophenone-3 and Benzophenone-4 can also be used as sunscreen products, where they protect the skin from damaging UV rays. Benzophenone-5 can be used for creams, lotions, gels, make-up, shampoo, conditioner, styling products, facial cleansers, self-tanner, sunscreen, and other fact and body care products. Benzophenone-1, Benzophenone-3, Benzophenone-4, Benzophenone-5, Benzophenone-9, and Benzophenone-11 all protect personal care and beauty products from deterioration by absorbing, reflecting, or scattering UV rays.

There are over 300 natural derivatives of Benzophenone, most of which are actively being researched for future chemical uses by scientists all over the globe. However, about a handful of those are commonly used today. Benzophenone is found in fruits, is especially present in grapes, and has a role as a photosensitizing agent and a plant metabolite. Benzophenone is usually produced by atmospheric oxidation of diphenylmethane in the presence of metal catalysts such as copper naphthenate. Benzophenone-1, -3, -4, -5, -9 and-11 are compounds made from 2-hydroxybenzophenone. The industry processing sectors for benzophenone are adhesive manufacturing, fragrances, paint + coating manufacturing, printing ink manufacturing, and synthetic dye + pigment manufacturing.

One derivative of benzophenone, oxybenzone (benzophenone-3) is prominent in all sunscreens and also many beauty products. Oxybenzone is rare in the sense that it provides broad-spectrum protection from both UVA and UVB rays. It is most often used in conjunction with other sunscreen agents. In the United States, oxybenzone was approved for use in the US by the FDA in the early 1980s. Revised as of April 1, 2013, the FDA allows oxybenzone in over the counter (OTC) sunscreen products up to 6%. In the European Union, it is allowed in sunscreens and cosmetics at levels of up to 6% and 0.5% respectively. In addition to the United States and the European Union, oxybenzone is also approved as a safe and effective sunscreen ingredient in Canada, Australia, and several ASEAN countries. Oxybenzone helps to maintain the stability of other cosmetic ingredients, and prevents their deterioration under the sun. Certain makeup products are designed to include sunscreen in them to provide an extra helpful feature to their customers. Lip balm, primer, foundation, tinted moisturizers, and self tanners are all products that contain sunscreen and are preserved by oxybenzone.

Cosmetic and beauty products are wonderful because no matter what they’re shopping for, people of all different skin tones and colors can find the product that suits them. It’s particularly easy because all you have to do is look at the color of the product and see if it’s something you’re interested in. But think about how difficult shopping for cosmetics would become if suddenly people couldn’t see the color of the lip gloss or the concealer they wanted to buy. It would be much more difficult for people to determine which shade they wanted to purchase if they were unable to see the color of the product at first glance. Thanks to benzophenone, this isn’t an issue in the cosmetic industry. Benzophenone can be added to plastic packaging as a UV blocker to prevent photo-degradation of the packaging polymers or the contents of the package. Using benzophenone allows manufacturers to package the desired product in clear glass or plastic. Without it, opaque or dark packaging would be required for all products.

Benzophenones and hindered amines light stabilizers (HALS) are widely used in polypropylene. Polypropylene is a thermoplastic polymer that has a large number of applications. A combination of stabilizers is used to obtain this desired stabilization; highly stabilized polypropylene contains an UV absorber, a phosphite stabilizer, and a nickel quencher or hindered amine light stabilizer.

Maxgard® 1800, our version of Benzophenone-9, is one of our products that is primarily used in the cosmetic industry for hair care products. It is an effective light stabilizer for protecting cosmetics from the damaging UV radiation and it stabilizes colors in various applications. In these cosmetics/perfumes, the stability is improved. Another product that’s used in the cosmetic industry is Maxgard® 1000, our version of Benzophenone-2. Its primary application is for product protection like clear lenses and other optically clear services. Maxgard® 1888 is soluble at 5% in water thus finding application as a UV absorber in cosmetics, hair care products, textiles, and water-based paints and inks to protect product color, fragrance and to protect the polymer that gives gel its structure.